This guide walks through how to choose the right SFP cage step by step—from understanding form factors and speed requirements, to aligning cage features with real deployment scenarios, and finally narrowing the decision down to a practical three-point checklist. Along the way, we’ll also show how GLGNET’s SFP cage solutions are designed to support these real-world engineering decisions across switching, storage, and telecom platforms.

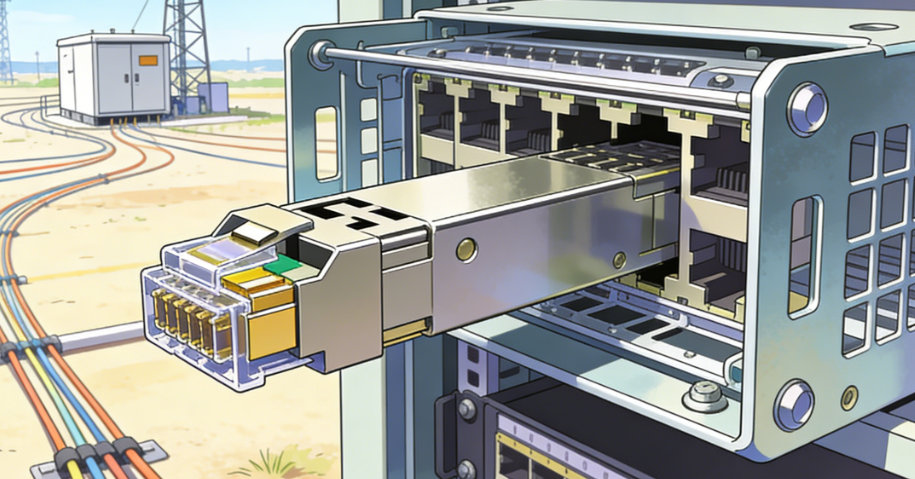

An SFP cage is a metal enclosure built into networking hardware—such as switches, routers, NICs, or optical systems—that provides the physical interface for an SFP transceiver. It guides the module into place, keeps it firmly seated through repeated insertions and removals, and adds a grounded shield around the port to help reduce EMI. In practice, the cage is what makes the front-panel SFP port feel precise and reliable, while supporting stable alignment and long-term mechanical durability.

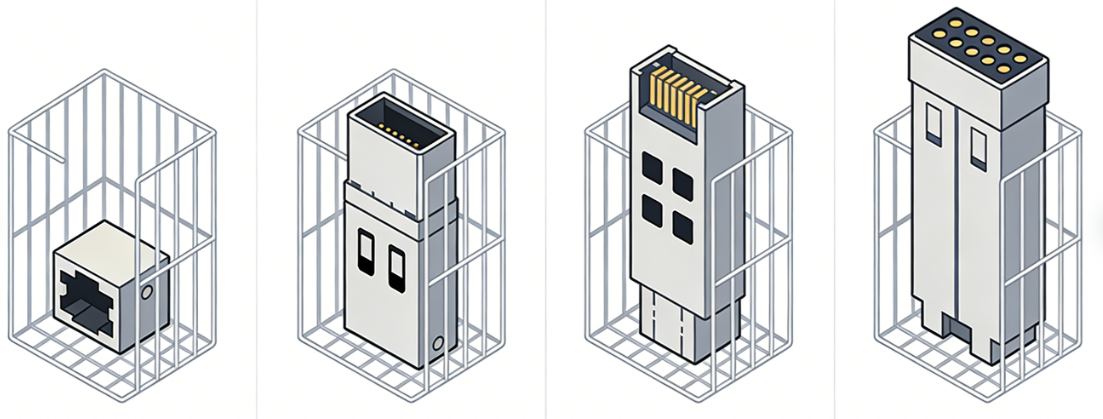

Before selecting an SFP cage, it’s worth taking a moment to separate SFP, SFP+, SFP28, and QSFP in your mind. On the surface—especially within the SFP family—these modules can look and feel almost identical when you plug them in, so it’s easy to assume the cage is one-size-fits-all. In practice, the module you’re designing around is what sets the rules: it determines the port interface the cage must physically support and the performance demands the cage/connector system has to meet.

That distinction becomes more important as speeds climb. When you move from 1G to 10G or 25G, the system has far less tolerance for small imperfections. Things like how cleanly the module seats every time, how continuous the grounding path is, and how well the metal structure controls interference can all show up as real-world stability and reliability issues. By locking in the form factor and speed class early, you’re much less likely to run into late-stage surprises—whether that’s a front-panel fit problem, SI/EMI headaches, or a cage that doesn’t behave consistently over repeated mating cycles. And if you choose a cage that aligns well with a broadly supported module ecosystem, you also make future maintenance and sourcing a lot easier when replacements or upgrades come into play.

|

Form Factor |

Typical Data Rate |

Port/Mechanical Footprint (High-level) |

Compatibility & Upgrade Notes |

Common Use Cases |

|

SFP |

1G |

Compact, single-lane module |

Mature ecosystem; widely available for long lifecycle designs |

Access switches, industrial networking, 1G links |

|

SFP+ |

10G |

Same physical family as SFP |

Higher SI expectations than SFP; strong multi-vendor supply |

ToR/aggregation, server NICs, 10G uplinks |

|

SFP28 |

25G |

Same physical family as SFP |

Tighter SI/EMI margin; common in modern data centers |

25G server access, leaf switches |

|

QSFP (QSFP+/QSFP28) |

40G / 100G (typical) |

Larger module; built for high-throughput ports |

Multiple generations—confirm platform support for the exact QSFP type |

Spine/core, high-speed uplinks, 40G/100G fabrics |

An SFP cage isn’t a standalone part—it’s a small component that has to “fit” the priorities of the system around it. A port-dense switch is usually driven by space efficiency and fast, repeatable assembly, while a storage platform tends to be far less forgiving about signal margin and long-term stability. If you start with the real deployment scenario, it becomes much easier to decide what to emphasize—port layout, EMI control, mounting method, or thermal support—without adding complexity that doesn’t meaningfully improve the end product.

That’s also how GLGNET approaches SFP cage design. The lineup covers single-port and multiport layouts, stacked configurations with integrated high-speed connectors, and practical add-ons such as EMI gaskets/springs, heat sinks, and light pipes—so the cage can be configured to match the platform requirements, rather than forcing a redesign elsewhere.

High Density, Frequent Insertion

In switches and routers, the SFP connector cage becomes a heavily used front-panel interface. The design goal is usually a careful balance between port density (1x1, 1xN ganged, or 2xN stacked), durability under repeated insertions, and manufacturing efficiency at scale.

To support these priorities, GLGNET offers multiport and stacked SFP cage designs, including options with integrated high-speed connectors that can simplify PCB work in dense layouts. As port counts climb and panel spacing gets tighter, EMI gasket and spring options help maintain shielding continuity and reduce coupling between neighboring ports. Combined with manufacturing-friendly mounting styles, these solutions are designed to keep assembly smooth while staying robust in real-world operation.

Stability and Margin First

Storage networking is typically less about squeezing in the most ports and more about steady, error-free performance over time. Since SAN systems often run 24/7 and can be sensitive to noise, the cage selection tends to revolve around signal integrity headroom, predictable EMI behavior, and secure, consistent module retention.

GLGNET’s SFP cage options for SAN use cases emphasize reliable grounding and shielding, with gasket or spring structures that help keep noise under control. In tighter thermal environments, optional heat-sink integration can help manage localized transceiver heat, supporting stable behavior across long operating cycles without compromising mechanical reliability.

Long-Haul Reliability, Field Serviceability

Optical transport and telecom equipment needs to stay stable in electrically noisy, always-on environments, while still being practical to service in the field. That combination makes mechanical alignment, continuous shielding, and front-panel usability especially important.

GLGNET supports these platforms with mechanically reinforced cage structures, robust EMI shielding options, and light-pipe solutions that bring clear status indication to the front panel. The result is a cage setup that helps protect long-haul link stability, while also making day-to-day identification and maintenance faster—an advantage in carrier-grade and remote deployments.

When it comes to selecting an SFP cage, a few early decisions tend to shape the entire design. In most projects, port layout, manufacturing alignment, and EMI control are the factors that have the greatest impact. If these are defined clearly at the beginning, everything that follows—such as thermal options, LED indication, or minor mechanical details—can be finalized with far less friction. GLGNET’s SFP cage solutions are developed around these practical considerations, offering flexible configurations that adapt to different platforms and production environments rather than forcing a one-size-fits-all approach.

Port layout is an architecture-level decision because it establishes the physical boundaries of the front panel. Choosing between a single-port cage, a ganged multiport arrangement, or a stacked layout directly influences how much panel space is available, how air flows through the system, how easily modules can be inserted and removed, and how complex PCB routing becomes.

This is where having layout options matters. GLGNET supports single-port, multiport, and stacked SFP cage designs, allowing designers to scale port density without rethinking the entire interface. In higher-density builds, cages with integrated high-speed connectors can also help ease routing constraints and keep the layout manageable. Selecting a layout that aligns with enclosure size and airflow from the start is critical—port-density changes made late in the process often cascade into EMI, thermal, and mechanical rework.

(Press-Fit / Through-Hole / SMT)

How the cage is mounted can have a bigger impact on success than many electrical specifications. Press-fit, through-hole, and SMT options each interact differently with PCB design rules, assembly processes, yield consistency, and rework strategy. A mounting choice that works for early samples may become a bottleneck once the design moves into volume production.

GLGNET addresses this by offering SFP cage solutions with multiple installation methods, including press-fit and through-hole cage assembly options, so teams can match the cage to their existing manufacturing flow. In practice, many designs struggle not because of performance limits, but because the production line can’t hold consistency or repairs become too costly. Aligning the cage choice with manufacturing reality early helps avoid those issues.

(Gaskets / Springs / Fingers)

EMI challenges often surface late in development—especially in compact systems, designs with dense port layouts, or platforms that combine high-speed links with fans and power circuitry. At that stage, last-minute fixes can be disruptive, leading to layout changes, additional testing, or mechanical revisions.

A more reliable approach is to account for EMI at the cage-selection stage. GLGNET provides EMI gasket and spring options that help maintain grounding continuity and consistent shielding, particularly when ports are closely spaced or multiple cages are installed side by side. Building EMI control into the cage from the beginning is usually faster, more predictable, and far more cost-effective than trying to retrofit solutions after issues appear during validation.

Conclusion

GLGNET’s SFP cage portfolio is designed to support this approach, with flexible layouts, multiple mounting options, and configurable EMI and thermal features that adapt to different platforms and production environments. Whether you’re building a dense switch, a mission-critical storage system, or carrier-grade optical equipment, choosing the right SFP cage early helps ensure stable performance, smoother manufacturing, and easier long-term maintenance.

Read more:

https://www.glgnet.biz/articledetail/how-to-choose-the-right-qsfp-dd-cage-for-high-power-optics.html

https://www.glgnet.biz/articledetail/what-is-the-difference-between-osfp-and-qsfp-connectors.html

FAQ

1.What does SFP stand for?

SFP stands for Small Form-factor Pluggable. It refers to a compact, hot-pluggable transceiver module used in networking equipment to connect fiber or copper links. SFP modules are commonly used for 1G, 10G, and higher-speed connections, depending on the specific SFP variant.

2.What is an SFP board?

An SFP board usually refers to a printed circuit board (PCB) that hosts one or more SFP cages and connectors. It provides the electrical interface between the SFP transceiver and the main system, handling signal routing, grounding, and power delivery. In many designs, the SFP board is part of a larger switch, router, or network interface card.

3.What is the SFP port in a firewall?

An SFP port in a firewall allows the device to use pluggable network interfaces instead of fixed Ethernet ports. This gives flexibility to choose different media types—such as fiber or copper—and different speeds based on deployment needs. SFP ports are often used for WAN connections, uplinks, or high-speed interfaces in enterprise and carrier-grade firewalls.

4.Is an SFP cage the same as an SFP module?

No. An SFP module is the removable transceiver that provides the optical or electrical interface, while an SFP cage is the metal housing mounted on the device that physically holds and aligns the module. The cage provides mechanical stability and EMI shielding, while the module handles signal transmission.

5.Can the same SFP cage be used for SFP, SFP+, and SFP28?

In many cases, yes—because SFP, SFP+, and SFP28 share a similar physical form factor. However, higher-speed applications place stricter requirements on signal integrity, grounding, and EMI control. While the cage may look the same, it must be designed to support the performance level required by the target speed to ensure reliable operation.