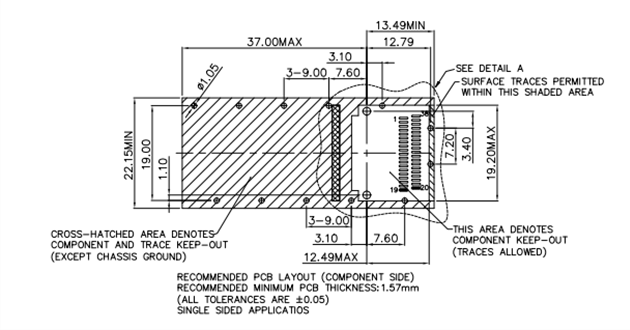

As 400G/800G optics push into the 15W–18W+ range, choosing the right QSFP-DD cage becomes a system-level decision—not just a mechanical one. In dense switches, cage design, heat-sink integration, and layout choices directly influence thermal performance, signal stability, and long-term reliability.

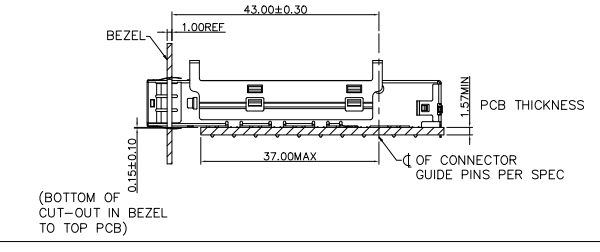

As optics move into the 15W–18W+ range, the QSFP-DD cage becomes part of the thermal design—not just a mechanical shell. The cage’s contact areas, heat-sink interface, and airflow clearance all affect how efficiently heat is removed during sustained operation.

On 400G/800G platforms that run beyond the familiar ~12W range, the module can’t carry the thermal burden on its own. In production, a poorly matched cage often shows up as higher case temperatures, throttling or intermittent link issues, and accelerated wear in dense port zones. A well-engineered QSFP-DD cage helps align cooling, airflow, EMI control, and signal stability as power density continues to rise.

For 15W–18W+ optics, it’s best to treat the QSFP-DD connector and heat sink as a single thermal package rather than a cage with an accessory. At sustained high power,“more airflow”alone often isn’t enough—an integrated heat sink provides the extra surface area needed to keep module case temperatures steadier across dense port banks and long-running workloads.

When choosing a QSFP-DD cage for high-power platforms,look for designs with factory-installed or configurable heat-sink options so the thermal solution can match the switch’s actual airflow pattern. This is where practical, system-level experience can shorten the validation cycle: GLGNET offers QSFP-DD cage solutions with integrated heat-sink designs and multiple profile options, helping teams align thermal performance with different cooling layouts and density targets without adding assembly complexity.

Common heat sink options

|

Heat Sink Type |

Best Use Case |

|

Fin-style |

Directional airflow, front-to-back cooling |

|

Pin-style |

Mixed or less predictable airflow / turbulence |

|

Custom profile |

AI/HPC platforms with unique airflow constraints or higher thermal budgets |

In many hyperscale and high-density deployments, the QSFP-DD cage is now expected to include a heat-sink solution as part of the baseline design. Teams often choose factory-fitted or configurable heat-sink profiles early on, so thermal validation can be met without late-stage changes to the chassis, fan settings, or airflow design.

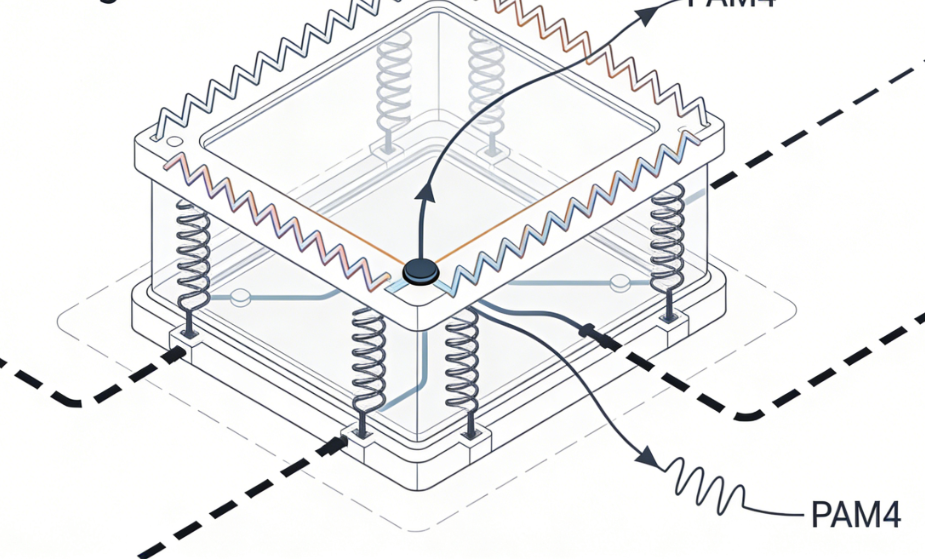

A common thermal guideline in high-power designs is to keep the module case temperature rise (T-rise) at ≤ 30°C above ambient. Staying within that range generally supports longer service life, helps keep PAM4 links stable over time, and aligns with typical operating limits specified by many module vendors.

In real systems, T-rise is shaped as much by the QSFP-DD cage as by the module. The biggest factors are heat-sink effectiveness, the airflow gap between the cage and PCB (especially in tightly packed port arrays), and how consistent the mechanical contact is from port to port. That’s why many OEMs prefer cage assemblies that are engineered and validated as an integrated unit—an approach GLGNET focuses on to reduce port-to-port variation and keep thermal behavior more predictable in production.

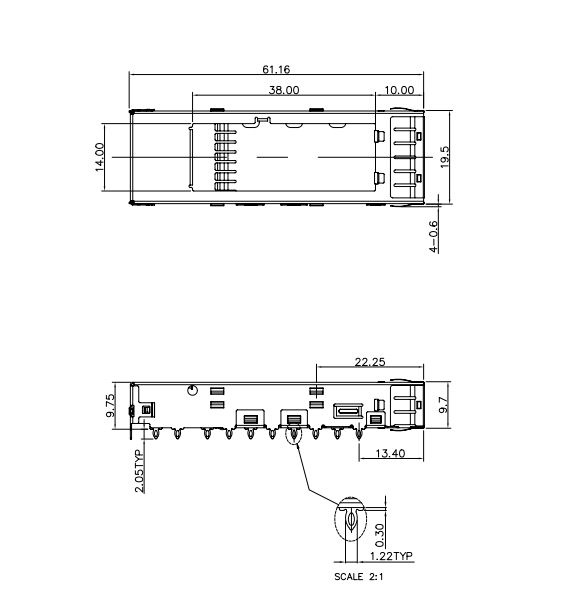

Stacked QSFP-DD cage layouts are a common pick when you need more thermal cushion. The extra separation between rows gives airflow a clearer path through the port area and leaves room for more capable heat-sink profiles without interfering with neighboring modules.

In practice, stacked designs usually deliver better cooling“headroom”and more freedom in heat-sink geometry. The trade-off is that their effectiveness still hinges on the chassis airflow pattern—lower rows may cool less efficiently in some systems—and the added spacing can slightly reduce maximum front-panel density versus tighter arrangements.

Belly-to-belly QSFP-DD connector designs are often chosen when port density and electrical performance are the priorities. This configuration is widely used in higher-end Ethernet switches because it supports compact faceplates while keeping routing clean and signal integrity stable at high speeds.

Thermally, the tighter geometry means you have to plan more carefully. Heat-sink height and airflow direction need to be controlled to avoid “thermal shadowing,” where one module’s heat sink disrupts cooling for the adjacent port—an effect that becomes more noticeable as optics move into the 15W–18W+ range.

|

Design Factor |

Why It Matters in High-Power, High-Density Systems |

What to Prioritize |

|

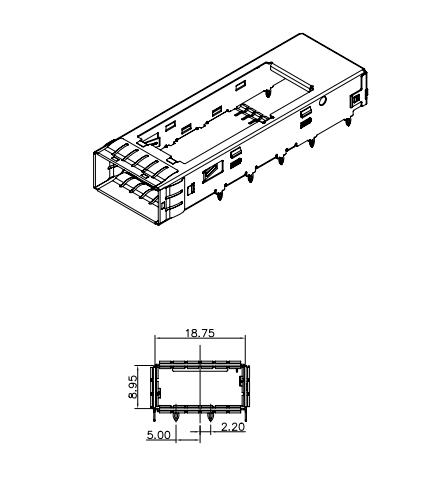

Light Pipe Integration |

Prevents LED alignment issues and reduces assembly variation |

Integrated light pipes matched to the cage/front panel |

|

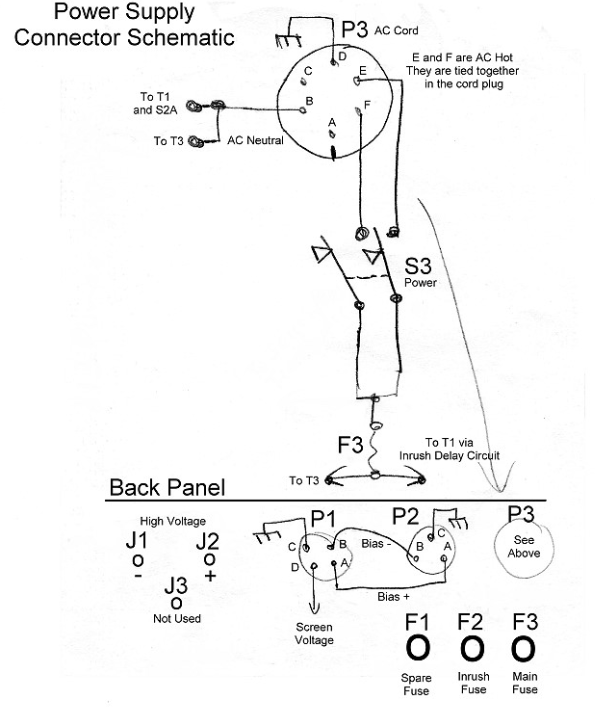

EMI Shielding & Signal Integrity |

Helps maintain link stability as power density and speeds increase |

Continuous EMI gaskets/springs + strong cage-to-panel grounding |

|

Mechanical Compatibility & Flexibility |

Improves design reuse across SKUs and reduces operational friction |

1×1/1×2/1×4 arrays, QSFP compatibility (if needed), tight tolerances |

For high-density, high-power platforms, an integrated light pipe built into the QSFP-DD cage helps eliminate a frequent source of line-side variation. With separate light pipes, minor movement during assembly can cause LED misalignment, uneven appearance between units, and unnecessary rework. An integrated approach keeps alignment consistent and makes high-volume builds easier to control. In practice, GLGNET offers QSFP-DD cage options with integrated light-pipe designs to improve assembly repeatability and reduce alignment risk on dense front panels.

As optics move to higher power and faster PAM4 signaling, EMI becomes a day-to-day stability concern—not just a compliance item—and the QSFP-DD cage plays a direct role in containment. Prioritize continuous EMI springs or gaskets, strong cage-to-panel grounding, and designs validated for 56G/112G PAM4 environments. In tightly packed port areas, EMI issues often show up as intermittent errors or sensitivity to neighboring ports even when temperatures look acceptable. This is why GLGNET focuses on robust shielding and grounding details in QSFP-DD cage designs for dense 400G/800G switch platforms.

A versatile QSFP-DD cage platform can reduce redesign work and allow the same mechanical stack to be reused across multiple switch SKUs. Check support for 1×1, 1×2, and 1×4 arrays, confirm QSFP compatibility if legacy optics are still in the roadmap, and pay attention to tolerance control. These details matter most in environments with frequent insert/remove cycles—labs, staging, and high-churn operations—where small mechanical variations can turn into long-term reliability or maintenance headaches. Many teams work with suppliers like GLGNET because they can support multi-configuration requirements while keeping production consistency in focus.

Conclusion

For high-power optics, a QSFP-DD cage is part of the thermal, EMI, and reliability design—not just the connector frame. Prioritizing integrated heat sinks, controlled T-rise, and the right cage layout helps avoid late-stage redesigns and improves production consistency. With proven 400G/800G high-density experience, GLGNET supports QSFP-DD cage solutions that balance thermal performance, signal integrity, and manufacturability.

Read more:

https://www.glgnet.biz/articledetail/what-is-the-difference-between-osfp-and-qsfp-connectors.html

https://www.glgnet.biz/articledetail/what-are-sfp-ports-used-for.html