This article focuses specifically on SFP cages with EMI gaskets: where the gasket sits, what problem it actually solves, how it compares with EMI springs or fingers, and when it’s truly needed. By looking at EMI from a cage-structure and integration perspective, we’ll also share practical design considerations—and how GLGNET approaches EMI-ready SFP cage solutions for different port densities and platform requirements.

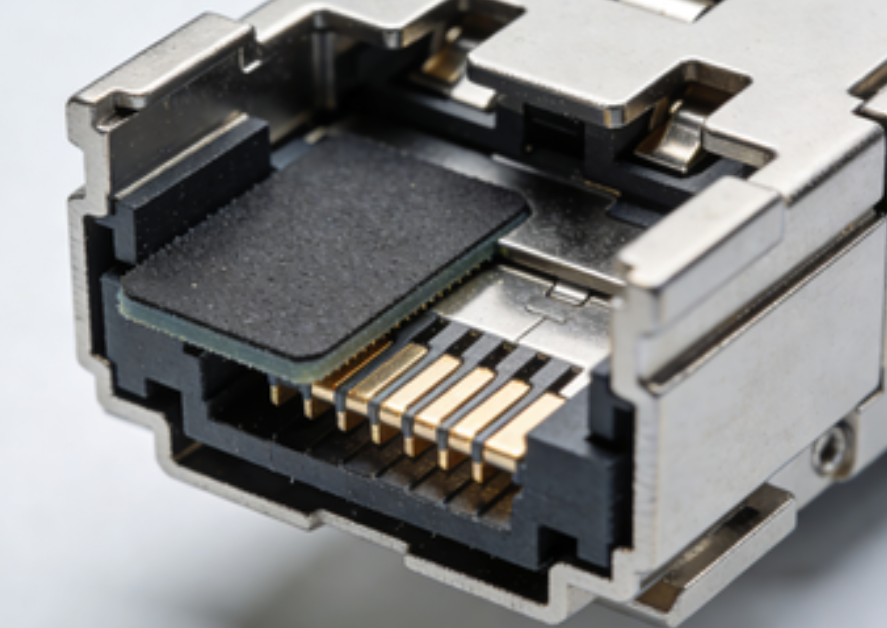

With an SFP cage, EMI performance often comes down to one simple principle: the shielding needs to behave like a single, continuous metal enclosure. The transceiver sits inside the cage, but the cage still has to make a clean, low-impedance connection to the front panel or chassis ground. An EMI gasket (or spring contact) supports that connection by closing small gaps before they become leakage paths.

In most designs, the EMI gasket sits around the cage-to-panel contact area, where panel cutouts and assembly tolerances tend to leave seams. On multiport layouts, it may also be used along the outer frame to keep the entire row well grounded. For stacked cages, the upper and lower layers create additional seam paths, so gasket placement becomes even more important at the panel boundary and other tolerance-sensitive contact points.

One thing to keep in mind: an EMI gasket won’t solve PCB routing or signal-integrity issues. Its value is mechanical and structural—it helps the SFP cage maintain metal-to-metal continuity and reduces seam radiation around the front-panel interface.

|

Feature |

EMI Gasket (on an SFP Cage) |

EMI Springs / Fingers (on an SFP Cage) |

|

Primary role |

Seals seams and improves shielding continuity at the cage-to-panel interface |

Maintains electrical contact by spring force, compensating for tolerances |

|

Best at |

Reducing seam leakage around panel cutouts; creating a more “closed” enclosure |

Handling tolerance stack-up, vibration, and repeated insertions |

|

Sensitivity |

More sensitive to panel cutout, surface finish, and the right compression force |

More forgiving; designed to flex and maintain contact over time |

|

Typical use cases |

High port density, tight panel spacing, strict EMI/EMC compliance |

Medium density designs, mature mechanical processes, frequent mating cycles |

|

Trade-offs |

Requires correct compression zone; can add assembly constraints if mis-specified |

May provide less “sealing” than a gasket in very tight, high-density seams |

In practice, EMI features on an SFP connector are usually chosen based on what the platform actually needs, not as an all-or-nothing decision. In dense multiport or stacked front panels—where seam paths multiply and compliance headroom can be tight—designers often combine an EMI gasket with springs or fingers to reduce leakage while keeping solid contact even when tolerances shift. For mid-density systems with a cleaner panel interface and well-controlled builds, springs or fingers alone are often enough. GLGNET supports both paths with SFP connector options that can be configured with EMI gaskets and/or spring contacts, so you can tune the shielding approach to your port density and compliance goals without adding unnecessary complexity.

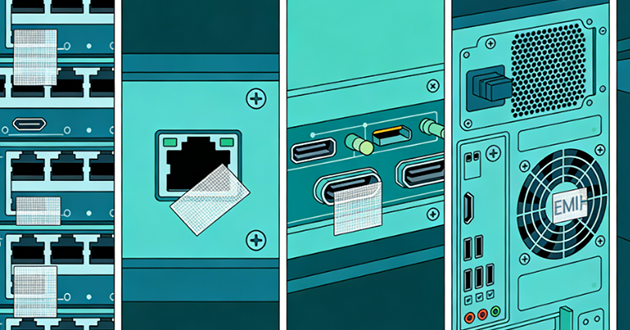

As an SFP cage layout gets denser, the number of seams around the cage-to-panel boundary increases, creating more places for leakage. In stacked designs, those seam paths multiply, so adding an EMI gasket helps keep the shielding more continuous across the entire port block.

With a tight panel opening, even small tolerance shifts can leave micro-gaps at the cage edge. An SFP cage EMI gasket provides a controlled contact surface, improving compression consistency and making the cage-to-panel interface more repeatable.

If the SFP connector grounding relies on a few small touch points—especially with plating variation, oxidation, or tolerance stack-up—EMI results can vary from unit to unit. A gasket helps stabilize metal-to-metal contact so the shielding loop stays reliable.

Fans, power supplies, PoE circuitry, and dense regulators can amplify weak seams near the front panel. An EMI gasket on the SFP cage helps reduce leakage at that boundary—often the same area where issues show up during validation.

When compliance margin matters, a gasket is a practical way to add structural shielding without reworking the entire port region. In many cases, selecting an SFP cage with an EMI gasket is the simplest path to extra headroom.

An EMI gasket only performs as intended when it operates within a defined compression range. Too little pressure leaves seams open; too much can complicate assembly or create unit-to-unit variation. For a gasketed SFP cage, the panel cutout and compression zone should be treated as part of the mechanical design from the start. GLGNET supports this by offering cage and gasket combinations that align with common panel thicknesses and cutout practices, helping teams achieve consistent contact without excessive tuning.

Reliable shielding over the product lifetime depends on stable metal-to-metal contact. Plating selection, surface finish, and contact geometry all affect how well grounding holds up after repeated insertions or long-term exposure to wear and oxidation. In GLGNET’s SFP cage designs, these contact surfaces are engineered with durability in mind, reducing the risk of shielding performance drifting after deployment.

For multiport SFP cages, EMI control is a system-level concern. It’s not enough for individual ports to make contact—the entire cage frame needs to act as a single grounded enclosure. Attention to outer-frame grounding and edge continuity becomes increasingly important as port density grows. GLGNET’s multiport cage options are designed to support this full-row continuity, with EMI features that scale cleanly as density increases.

Stacked cages enable higher port counts but also magnify tolerance stack-up effects. Small alignment differences between upper and lower rows can introduce localized gaps at the panel interface. Matching gasket selection with cage geometry helps maintain even contact across the stack. GLGNET’s stacked SFP cage platforms are developed to support repeatable alignment in dense designs, where EMI performance and mechanical consistency go hand in hand.

Effective shielding shouldn’t come at the cost of usability. Over-compression or panel interference can make module insertion feel stiff or inconsistent, slowing service and increasing wear. By offering configurable EMI solutions alongside options such as integrated light-pipe support, GLGNET enables designers to balance EMI requirements with smooth insertion and straightforward field maintenance—especially in applications with frequent module changes.

Conclusion

An EMI gasket on an SFP cage is not a universal requirement, but in the right conditions it can make a meaningful difference. High port density, tight panel cutouts, imperfect grounding paths, and noisy front-panel environments all increase the risk of seam-related EMI. In those cases, adding a gasket is often the most direct way to improve shielding continuity without redesigning the entire port area.

Read more:

https://www.glgnet.biz/articledetail/how-to-choose-the-right-sfp-cage-for-our-setup.html

https://www.glgnet.biz/articledetail/how-to-choose-the-right-qsfp-dd-cage-for-high-power-optics.html

FAQ

1.What is the purpose of an EMI gasket?

An EMI gasket helps keep shielding continuous between metal parts (for example, an SFP cage and the front panel). It closes small gaps and reduces seam leakage. It won’t fix PCB routing or signal integrity problems.

2.Is SFP+ backward compatible with SFP?

Often yes in terms of fit—many SFP+ ports can accept SFP modules. But support depends on the device (hardware/firmware), so verify whether 1G operation is supported.

3.How do you use an EMI gasket on an SFP cage?

It’s typically placed at the cage-to-panel interface and must be compressed correctly. Proper panel cutout, surface finish, and grounding help it work consistently.

4.Do all SFP cages need an EMI gasket?

No.Gaskets are most useful for high-density/stacked ports, noisy platforms, or compliance-driven designs. Lower-density ports with solid spring contacts may not need one.

5.What’s the difference between an EMI gasket and EMI springs/fingers on an SFP cage?

A gasket mainly seals seams to reduce leakage. Springs/fingers mainly maintain contact across tolerances and repeated insertions. Some designs use both for extra margin.