In this article, we’ll break down what EMI springs are, where they sit on an SFP cage, and why they matter for shielding and ground bonding. We’ll also address a common misconception: whether spring fingers can be treated as a meaningful thermal path, and what to do instead when module power rises.

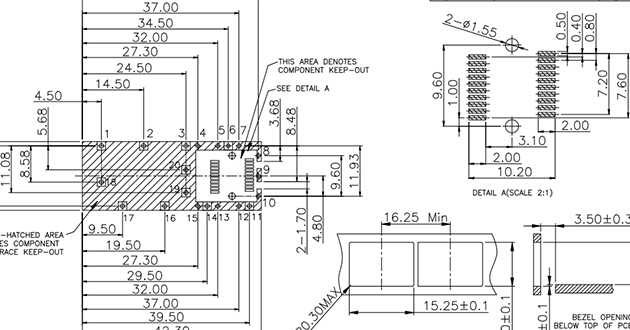

EMI springs—often called spring fingers—are small conductive tabs stamped and formed as part of the SFP cage. They’re usually positioned around the outer edge of the cage, right where it mates to the front panel or chassis. Once the cage is installed, the fingers flex slightly and keep gentle, continuous pressure on the metalwork, so the cage stays well bonded electrically even when there are small tolerance differences, minor movement, or vibration.

In many designs, EMI springs work alongside EMI gaskets or other compliant shielding features (the product page lists options like “EMI gaskets or springs”). The goal is simple: make the interface around the panel cutout electrically continuous, with as few weak spots as possible. By “filling in” tiny gaps and uneven contact areas, the springs help prevent the opening from becoming an easy leak point—reducing EMI escape and improving the enclosure’s overall shielding performance.

In most network systems, the front-panel opening around an SFP connector is one of the easiest places for EMI to leak out. The cutout in the panel, the tiny seams between the SFP cage and the panel, and the edges where multiple metal parts meet can all become unintended escape routes. Put simply, a narrow gap can behave like an accidental radiator at certain frequencies (often described as the slot effect). That’s why hardware that “almost passes” in the lab may still fail—or only scrape by—because of small details right at the port interface.

This is where EMI springs (often used with EMI gaskets) make a real difference on an SFP cage. They create multiple compliant contact points around the cutout, helping maintain a more continuous conductive boundary at the panel interface. Compared with relying only on rigid metal-to-metal contact, spring features handle real-world variation better—tolerance stack-up, panel flatness, and small shifts over time—so shielding performance is more likely to stay stable after assembly and through the product’s life.

As port density goes up—from single-port to multi-port and stacked configurations—the risk grows. More ports mean more openings packed into a small area, which also means more seams and edges. In that situation, one weak contact point on an SFP connector can quickly turn into a local leakage hotspot. So the key question in high-density designs isn’t just “did we add shielding?”—it’s “is the shielding continuous, and will it stay continuous after build, handling, and operation?”

From a production standpoint, repeatable EMI performance usually comes down to two things: consistent geometry and controlled materials/processes. Spring force window, contact layout, surface finish, and how the SFP cage mates with different panel materials or coatings can all change what you see in test. That’s why GLGNET frames SFP connector development as a system-level design problem—combining precision mechanical design with signal-integrity awareness—so EMI spring/gasket features are built into the structure from the start, rather than added as a last-minute fix.

Good shielding is more than “having metal around the opening.” It also depends on whether that metal is reliably tied to chassis ground. If the electrical bond between an SFP port and the chassis is inconsistent, parts of the cage/panel area can effectively “float,” giving common-mode energy room to circulate. In the worst case, the structure that should help contain noise can start behaving like part of the radiator.

This is where EMI springs on an SFP port matter beyond shielding. By maintaining steady, compliant contact pressure between the cage and the panel/chassis, they make the bond more consistent across real builds. Another way to think about it: spring fingers don’t just reduce mechanical gaps—they help keep the cage referenced to the chassis in a more stable, repeatable way. With that contact condition under control, the interface impedance is less likely to drift due to tolerance stack-up, slight loosening, vibration, or handling.

At the system level, this usually shows up as:

Cleaner return paths for common-mode energy, reducing unexpected coupling and front-panel “hot spots.”

A more consistent reference environment near high-speed ports, which becomes increasingly important as ports get denser and routing more complex.

That’s why many engineering teams view EMI spring features as doing double duty: shield continuity + ground continuity. And in volume production, getting that continuity to behave the same unit after unit takes more than a good drawing. It hinges on contact force consistency, contact placement, assembly repeatability, and long-term behavior under vibration and surface aging. GLGNET approaches SFP cage development with those production realities in mind—focusing on structural and material decisions that make contact behavior easier to measure, validate, and repeat.

A related question often comes up during bring-up: if EMI springs create metal contact, can they also act as a thermal path? In practice, they may provide a small amount of heat transfer, but they shouldn’t be treated as the primary route for cooling.

Spring-based thermal conduction is hard to rely on for three main reasons:

Limited effective contact area

Spring fingers typically touch at points or short lines, so the true conduction area is small.

Thermal resistance varies from unit to unit

Plating condition, oxidation, contact pressure, and tolerance stack-up all influence the interface. Thermal design is driven by worst-case consistency—and spring interfaces are difficult to keep identical across builds.

They’re designed for electrical bonding, not predictable heat coupling

Springs prioritize compliance and stable electrical contact, not a controlled thermal interface.

A more dependable approach is to treat thermal management as its own design track. As module power increases, the thermal path should be built around dedicated, controllable, and verifiable solutions—heat sinks, thermal pads, engineered coupling features, or chassis conduction routes—rather than depending on a contact interface that can shift with assembly variation. In that sense, EMI springs can be a “bonus” contributor, but thermal performance should be anchored by purpose-built thermal structures.

GLGNET typically applies this same separation of concerns in SFP module planning: spring features stabilize shielding and bonding, while higher-power platforms use clearer thermal structures so validation is straightforward and results stay predictable.

Read more:

https://www.glgnet.biz/articledetail/what-is-an-sfp-module.html

https://www.glgnet.biz/articledetail/what-is-the-difference-between-sff-and-sfp-module.html

Conclusion

EMI springs are small parts with outsized impact because they help keep the front-panel SFP interface electrically continuous in the real world—across tolerance stack-up, assembly variation, and long-term vibration. In practice, their value shows up in two core roles: improving shield continuity to reduce leakage around the cutout, and stabilizing ground bonding so the cage stays referenced to chassis ground.

As for heat, spring fingers may offer a minor side benefit, but they’re not a dependable cooling strategy—high-power designs still need dedicated thermal structures you can control and validate. With that system-level mindset, GLGNET builds EMI spring/gasket features into SFP cage designs from the start, focusing on repeatable contact behavior so performance stays consistent from prototype to volume production.