In Ethernet networks, the cables themselves often get most of the attention, but the RJ45 connector is just as critical to overall performance and reliability. From the physical fit to shielding, wiring standards, and specialized form factors, each aspect of the connector can influence signal integrity, throughput, and long-term stability.

This article is a detailed guide to understanding the key differences between RJ45 connectors, how they affect network performance, and what to consider when selecting the right connector for your installation.

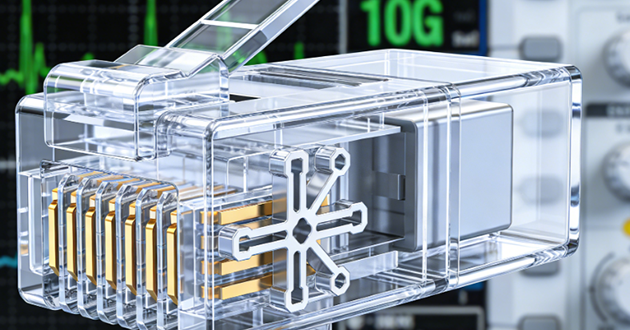

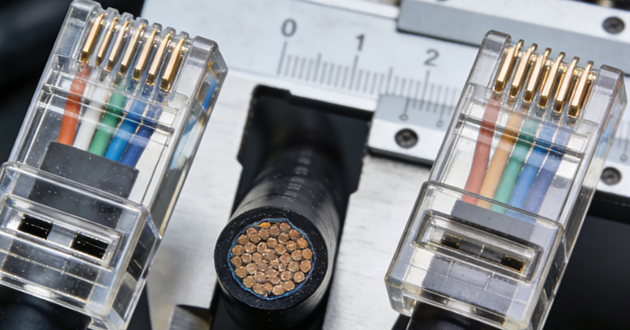

A reliable Ethernet link depends as much on the RJ45 connector as on the cable itself. What seems like a simple plastic plug is in fact a precision component engineered to match specific cable dimensions. Three aspects determine whether the fit is correct: the copper conductor thickness, the diameter of the insulated conductor, and the size of the outer jacket. Even a small difference, such as moving from 24 AWG conductors in Cat5e to 23 AWG conductors in Cat6, can affect how the connector’s pins align and pierce the insulation, influencing both contact stability and long-term reliability.

The conductor type also plays a critical role. Connectors designed for solid-core cables use side-cutting contacts that bite cleanly into the copper, while connectors made for stranded patch cords rely on sharper, pointed contacts that slip between strands. Using the wrong type may appear functional at first but often results in intermittent connectivity or shortened lifespan. Jacket size and pair alignment introduce another challenge: cable diameters vary across categories and manufacturers, and thicker Cat6A jackets are harder to manage without the help of load bars or inserts. These components guide the pairs into place while maintaining jacket grip, reducing the risk of excessive untwisting.

Preserving the twist of each pair is essential to maintaining signal integrity. Although standards permit a small amount of untwist near termination, the closer the pairs remain to their natural twist rate, the better the crosstalk and return loss performance. High-performance connectors are designed to minimize untwist, which becomes particularly valuable in Cat6A or higher-speed installations. In practice, when the RJ45 connector is not physically matched to the cable, the entire channel will fail to deliver on its rated performance — no matter how high the category printed on the cable jacket.

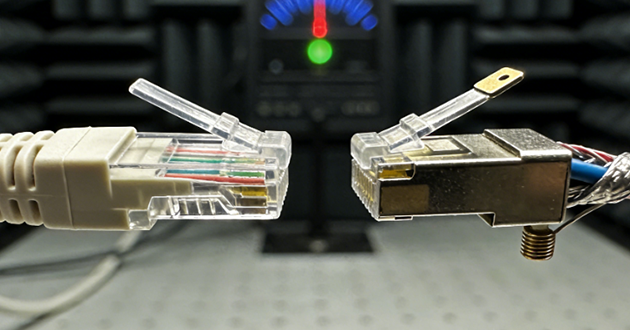

Choosing between a shielded and unshielded RJ45 connector is not about picking a “premium” option but about matching the connector to the operating environment. For homes and small offices, unshielded jack connectors paired with UTP cable are usually sufficient, as twisted pairs inherently cancel much of the ambient noise. However, in environments where electromagnetic interference is significant — such as manufacturing floors, hospital equipment rooms, or data centers with dense parallel runs — shielded connectors make a measurable difference in performance and reliability.

The effectiveness of shielding depends entirely on continuity. For a shield to function, the cable’s foil or braid must make solid contact with the connector’s metal shell, which in turn must bond to a grounded system. If a shielded cable is terminated with an unshielded connector, the shielding becomes useless. Equally important is the grounding strategy: while shields bonded at both ends may seem logical, they can form ground loops that amplify rather than suppress noise. Experienced installers often rely on single-point grounding or careful chassis bonding to ensure stability.

Connector construction also matters. Shielded RJ45 connectors are usually reinforced with metal housings, clamps, or even weatherproof seals. These features not only preserve electrical continuity under stress but also protect the termination from moisture, vibration, or bending. Without secure clamping of the foil or drain wire, the shielding is effectively broken. Shielded connectors are most beneficial when cables are routed near heavy machinery, fluorescent lighting, or power conduits, or when 10G Ethernet is deployed in dense bundles where alien crosstalk is a concern. For standard residential or office applications, unshielded solutions remain more than adequate.

The key takeaway is that shielding is only effective when the entire system — cable, RJ45 jack connector, and grounding — is designed and installed as a whole. A shielded connector is not inherently “better”; it only delivers an advantage when continuity and grounding are carefully planned and executed.

When you push for higher network speeds or longer transmission distances, the weak point is rarely the bulk cable alone. More often, it’s the small but critical components along the path — the rj45 connector among them. Each Ethernet category, whether Cat5e, Cat6, Cat6A, or Cat7, enforces stricter tolerances for near-end and far-end crosstalk, insertion loss, and return loss. As signal frequencies climb into the gigahertz range, the connector’s physical design has a direct and measurable impact on those parameters.

If you are working with Cat6A cabling, for example, you’ll find that well-designed connectors use features like staggered contact layouts or molded separators to maintain pair spacing and suppress alien crosstalk. Impedance continuity becomes equally critical — even a slight geometric shift inside the plug can create reflections that show up as return loss, raising error rates on the line. And in applications involving PoE, the plating and contact material matter just as much: poor contact resistance translates into heat buildup, which accelerates wear and risks service interruptions.

For you as an installer, it isn’t enough to trust the “Cat6A” or “Cat7” printed on the packaging. The real assurance comes from checking detailed specifications, verifying performance figures, and validating the entire channel with a certifier. From a system-level view, a link will only perform to the standard of its lowest-rated element. That means choosing the right rj45 connector is every bit as important as the cable itself if your goal is dependable gigabit or multi-gigabit networking.

From the outside, every rj45 jack connector looks the same. Yet the way you terminate its eight conductors determines whether you end up with a straight-through link or an accidental crossover. The two accepted wiring standards, T568A and T568B, only swap the positions of the green and orange pairs, but that subtle difference becomes significant if you are aiming for a consistent installation.

As an installer, your concern isn’t whether you prefer A or B — it’s whether you stick to one scheme across the site. Mixing them introduces crossover cables that modern devices may sometimes tolerate thanks to auto-MDI/MDIX, but relying on that feature is poor practice and a recipe for confusion during fault isolation. What matters more is preserving the integrity of differential pairs: if you split a twisted pair or reverse its polarity, the PHY may still show continuity, but the signal quality will collapse under load.

That’s why wiring hygiene goes beyond continuity tests. A professional validation includes checks for split pairs, near-end crosstalk, and return loss, making sure your terminations actually meet category performance. Documenting the chosen scheme and labeling panels clearly ensures that future technicians won’t be left guessing. If you treat wiring standards as part of disciplined rj45 connector practices, you spare yourself and your clients from hours of unnecessary troubleshooting down the line.

Once you move beyond straightforward office cabling, you realize the standard clear plastic plug is only one option. In the field, different rj45 jack connector form factors are built to solve problems that range from harsh environments to tight rack spaces. Choosing among them requires balancing mechanical durability, electrical performance, and practical maintenance.

If you’re working outdoors or in an industrial plant, ruggedized connectors with sealed housings, metal shells, and locking threads provide protection against dust, vibration, and moisture. Their value lies not just in physical toughness but also in maintaining shield continuity when mated with corresponding jacks. In contrast, when your challenge is high port density in a data center or compact device, low-profile connectors allow more ports per rack unit but may demand stricter impedance control to preserve high-speed performance.

For technicians in the field, tool-less and pass-through connectors offer another trade-off. They speed up termination by letting conductors pass through for visual confirmation before trimming, but budget versions often sacrifice impedance stability and long-term reliability — particularly when used in Cat6A or higher applications. Add-ons like molded boots, snagless tabs, and reinforced latches may seem minor, but in racks where cables are moved frequently, they make the difference between a stable connection and a recurring failure. And if your project involves high-power PoE, you also need to account for connector heating, since poor contact resistance in a dense patch panel can escalate into thermal problems.

From a practical standpoint, the best choice of rj45 jack connector is guided by the installation environment, the network’s bandwidth goals, and the long-term maintenance model. A connector that combines verified electrical performance with mechanical resilience reduces downtime, lowers support costs, and ensures that your cabling infrastructure stands up to real-world conditions.

Performance

When the RJ45 jack connector is carefully matched to the cable it serves, the network can deliver its full rated throughput without compromise. A well-fitted termination preserves impedance alignment, keeps the twist of each pair intact, and allows the contacts to bite cleanly into the conductor. These small details add up to stable bandwidth, consistent latency, and a data link that behaves exactly as the Ethernet specification intends.

The opposite is also true: a poorly chosen connector undermines performance in subtle but damaging ways. Pins that don’t seat properly increase resistance, excessive pair untwist raises susceptibility to crosstalk, and small impedance mismatches generate reflections that chip away at signal quality. To the end user, these electrical imperfections reveal themselves as fluctuating speeds, retransmissions, or links that collapse when traffic peaks. In high-speed environments such as 1G, 2.5G, or 10G Ethernet, the connector is not a decorative accessory — it is a critical element that determines whether the channel performs at design capacity.

Reliability

Beyond raw speed, long-term stability is shaped heavily by the choice of RJ45 jack connector. In electrically calm residential or office settings, unshielded terminations are usually adequate. But in data centers, factories, or hospitals where cables run beside motors, fluorescent lighting, or dense wiring bundles, the difference between shielded and unshielded connectors often dictates whether the network remains dependable over time. A shielded connector, properly bonded with the cable’s foil or braid and tied into a grounding strategy, acts as a defensive layer that keeps interference away from the signal path.

Reliability also depends on mechanical resilience. Connectors with reinforced housings, proper strain relief, and durable latch mechanisms withstand repeated patching and environmental stress without loosening or failing. In contrast, a low-quality plug may pass initial continuity tests but degrade quickly under vibration or heat, leading to intermittent faults that are notoriously difficult to diagnose. In mission-critical environments, where downtime carries real costs, overlooking the physical and electrical role of the RJ45 connector can turn an otherwise well-designed cabling system into a persistent weak point.

Conclusion

Ultimately, the RJ45 connector is far more than a simple plastic plug; it is a precision-engineered component that directly impacts network performance, reliability, and maintainability. By selecting connectors that match cable categories, follow consistent wiring standards, and suit the environmental demands of your installation, you safeguard both the speed and longevity of your network.