This article will explore the differences between SFP to RJ45 interfaces, detail the technical considerations for conversion, and highlight scenarios where conversion may not be advisable—helping you make informed decisions in your network design.

Discover high-quality single and multiport SFP cages and connectors from GLGNET—trusted by global partners for reliable performance in Fibre Channel and Ethernet applications.

An SFP port, short for Small Form-factor Pluggable, is a compact, swappable slot commonly used on devices like switches and routers. Instead of being fixed to one connection type, it lets you plug in different modules—either for fiber or copper (RJ45)—depending on your needs. For example, fiber modules are great for longer distances and higher speeds, while copper modules are better suited for short-range Ethernet over regular network cables like Cat5e or Cat6. Thanks to this flexibility, SFP ports are especially handy in networks that mix fiber and copper connections or require frequent upgrades.

An RJ45 port is the standard Ethernet socket you’ll find on most computers, routers, and network switches. It connects to network cables—usually Cat5e, Cat6, or higher—to carry data over copper wires. While it doesn’t offer the hot-swappable flexibility of an SFP port, it’s simple, widely compatible, and ideal for everyday local network connections. Most RJ45 ports support speeds like 100Mbps, 1Gbps, or even 2.5Gbps, making them a reliable choice for short-distance, high-speed communication in homes and offices.

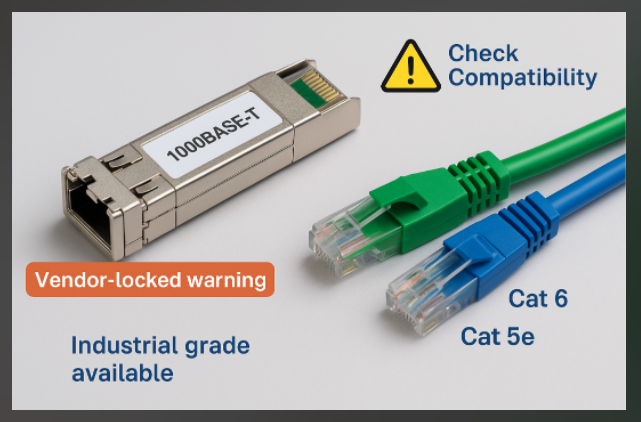

Yes, it is possible to convert an SFP to RJ45 by using a specialized module known as an SFP-to-RJ45 copper transceiver. These transceivers, often built on the 1000BASE-T standard, allow a Gigabit Ethernet connection over standard Cat5e or Cat6 copper cables by plugging directly into an SFP slot. However, while this offers flexibility, it is not a universal solution and comes with important technical considerations.

First, not all SFP slots are compatible with copper transceivers. Some network devices—particularly older hardware or vendor-locked systems—may only accept fiber modules or require proprietary firmware-coded SFPs, meaning they may reject generic third-party transceivers. In such cases, only brand-specific copper SFPs (e.g., Cisco, Juniper, HP) will work reliably, and using unsupported models could result in errors or a complete failure to establish a link.

Second, copper SFP modules have performance and environmental constraints. They generally support a maximum speed of 1Gbps and are limited to about 100 meters in transmission distance, which is sufficient for most office and data center setups but inadequate for long-distance backbone links. Additionally, these modules generate more heat than fiber transceivers due to the nature of electrical signal transmission, making thermal management a concern—especially in densely packed switch racks or passive-cooled enclosures.

Despite these limitations, copper SFP modules are extremely valuable in certain environments. For example, they are ideal when upgrading a network incrementally—allowing you to connect new fiber-capable switches to legacy copper-based infrastructure without needing media converters or replacing existing cabling. This makes them particularly attractive for SMBs, branch offices, or edge deployments, where budget, simplicity, and backward compatibility are key priorities. Moreover, they enable greater modularity in network design, letting administrators choose media types based on actual deployment needs rather than being locked into a fixed port type.

Want a deeper understanding of how QSFP ports can be converted to RJ45?

https://www.glgnet.biz/how-to-convert-qsfp-to-rj45-for-network-connection

Converting an SFP port into an RJ45 Ethernet interface is a practical solution for extending copper connectivity on network devices originally designed for fiber or modular connections. This approach not only leverages existing copper cabling infrastructure but also enhances network flexibility by allowing seamless integration of copper-based devices into SFP-dominated equipment. Below is a comprehensive and in-depth guide to facilitate a smooth and reliable conversion process.

The cornerstone of this conversion is the selection of a suitable copper SFP transceiver module. These transceivers generally conform to the IEEE 802.3ab 1000BASE-T standard, supporting Gigabit Ethernet over twisted-pair copper cables such as Cat5e or Cat6. However, compatibility extends beyond just the physical layer standard. Many network equipment manufacturers enforce vendor lock-in mechanisms, whereby their devices accept only certified or branded transceivers. This can be enforced by firmware checks or hardware authentication protocols, so it is critical to verify compatibility with the specific model and firmware version of your switch or router.

Moreover, consider environmental and operational parameters such as maximum supported cable length (typically up to 100 meters), operating temperature range, and whether the transceiver offers industrial-grade resilience for harsh conditions. Modules designed with enhanced heat dissipation or ruggedized components ensure stable operation in enclosed racks or locations with limited airflow. To mitigate any risk of incompatibility, always consult the official device documentation or the manufacturer’s transceiver compatibility list prior to purchase.

After acquiring the proper transceiver, the physical installation must be performed with care to avoid damage and ensure optimal operation. Most modern SFP slots support hot-swapping, which means the module can be inserted or removed without powering down the device, minimizing network downtime. However, always refer to your device’s manual to confirm hot-swap capability and any specific procedures.

When inserting the module, align it carefully with the SFP cage, ensuring that the connector pins and housing are matched correctly. Avoid applying excessive force— the transceiver should slide in smoothly and click securely into place. Many modules feature a retention latch or tab to lock the module and prevent accidental dislodging; make sure this mechanism is fully engaged. If insertion feels obstructed or the module does not seat properly, stop and verify the orientation and model number—forcing the module can damage both the device and the transceiver.

With the copper SFP module securely installed, the next step is cabling. Connecting a reliable RJ45 Ethernet cable is fundamental to maintaining network integrity. While Cat5e cable is generally adequate for Gigabit Ethernet transmissions within 100 meters, Cat6 cable offers improved performance through better shielding and reduced susceptibility to electromagnetic interference (EMI), which is particularly beneficial in electrically noisy environments or longer cable runs.

Inspect cables for any physical damage, such as bent pins, cracks in the jacket, or kinks, as these imperfections can introduce packet loss or speed degradation. Additionally, maintain proper cable management to avoid sharp bends or crushing, which can compromise signal quality. The SFP transceiver and connected device will handle automatic negotiation of link speed and duplex mode, typically establishing a full-duplex 1 Gbps connection without manual intervention.

The final step is to ensure the network device correctly recognizes the copper SFP transceiver and that the link is stable and operational. Most contemporary switches and routers have diagnostic LEDs near each port that visually indicate link status— a steady or blinking light commonly signals an active connection. For deeper verification, access the device’s management interface via a web GUI or command line interface (CLI) to confirm that the transceiver is detected and that the port status reports “link up.”

In scenarios where the module is not recognized or the link fails to establish, investigate potential causes such as firmware incompatibility or misconfiguration. Firmware updates often include expanded transceiver support and bug fixes, so keeping device software current is important. Additionally, consult vendor resources or technical support to resolve persistent issues, as some devices may require manual enablement of copper SFP ports or specific settings adjustments.

Having trouble getting your SFP port to work after conversion?

https://www.glgnet.biz/why-is-my-sfp-port-not-working-common-issues-and-fixes

Summary

By attentively selecting the correct copper SFP transceiver, carefully installing the module, using high-quality cabling, and validating device recognition and link status, you can confidently convert an SFP port into an RJ45 Ethernet interface. This conversion empowers your network with versatile copper connectivity while ensuring reliable performance and stability tailored to your environment.

When you require high-speed connectivity beyond 1 Gbps: Copper SFP modules adhering to the 1000BASE-T standard are limited to Gigabit speeds and cannot support faster Ethernet standards such as 10 Gigabit Ethernet (10G) or higher. If your network demands higher bandwidth or future-proofing with multi-gigabit speeds, relying on fiber optic SFP modules is essential to meet those requirements.

For long-distance links that exceed copper cable limitations: RJ45 copper connections typically have a maximum reliable transmission distance of around 100 meters. In contrast, fiber optic cables can extend communication links over several kilometers without signal loss or degradation. If your network topology involves distances beyond the copper reach, converting to RJ45 is not advisable, and fiber optics should be the preferred medium.

In environments demanding minimal latency and high reliability, such as data centers: Fiber optic connections offer superior signal integrity, reduced latency, and greater resistance to electromagnetic interference (EMI) compared to copper cables. Data centers and latency-sensitive applications benefit significantly from fiber’s stable and low-noise transmission, making copper-based SFP modules unsuitable for these high-performance scenarios.

Learn more:

Curious about the difference between SFP modules and SFP cages? Don't miss this breakdown:

https://www.glgnet.biz/sfp-vs-sfp-cage-whats-the-real-difference

Still deciding between SFP and RJ45 connectors for your network design? We’ve got you covered:

https://www.glgnet.biz/how-to-choose-between-sfp-and-rj45-connectors-for-your-network

Conclusion

In summary, by carefully selecting a compatible copper SFP transceiver, properly installing the module, using high-quality RJ45 cabling, and thoroughly verifying device recognition and link status, you can effectively convert an SFP port to an RJ45 Ethernet interface, expanding copper connectivity options.