In this guide, we’ll break down GLGNET SFP LC connectors and SFP SC connectors differences, key technical considerations, and help you decide which connector best fits your network requirements.

If you’re also comparing different SFP hardware options, don’t miss our article on SFP vs SFP+ Cage: What’s the Real Difference?

https://www.glgnet.biz/articledetail/sfp-vs-sfp-cage-whats-the-real-difference

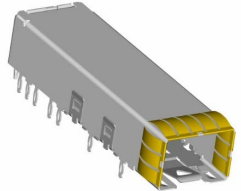

SFP modules play a vital role in fiber optic communication systems, offering reliable, high-speed connectivity for both short-range links and long-distance transmissions. Within this context, terms like SFP LC connector and SFP SC connector refer to the specific types of fiber interfaces used on the SFP module itself, which directly determine how the transceiver connects to the fiber optic cable.

LC stands for Lucent Connector, a design well-known for its compact size and space-efficient structure.SFP LC connectors utilize a 1.25mm ferrule, which allows engineers to maximize port density on network equipment—an essential requirement for modern, space-constrained environments. Due to these advantages, the LC interface has become the standard for most SFP and SFP+ modules used in data centers, enterprise networks, and high-performance telecom systems where rack space is limited, but network capacity must be maximized.

In comparison, the SFP SC connector—short for Subscriber Connector or sometimes referred to as Standard Connector—is based on an older, larger design. Featuring a 2.5mm ferrule and a straightforward push-pull mechanism, SC SFPs offer robust, reliable connections but with a larger footprint than LC options. Despite their size, SFP SC connectors continue to see use in legacy networks, certain industrial installations, and building backbone systems where space limitations are less critical, and durability is prioritized.

Found in next-generation network hardware such as high-speed switches, routers, dense patch panels, 10G/40G links, and telecommunications equipment where high port density and space efficiency are key design considerations.

Frequently used in existing infrastructure, older fiber optic systems, or point-to-point fiber connections, particularly where ease of use, durability, or lower density requirements make the SC form factor suitable.

Understanding the practical differences between an SFP LC connector and an SFP SC connector helps engineers and installers make informed decisions when selecting components, ensuring proper compatibility and optimal network performance across different types of fiber optic deployments.

Quick Comparison: LC vs. SC SFP

|

Feature |

LC Connector |

SC Connector |

|

Ferrule Size |

1.25mm |

2.5mm |

|

Size & Footprint |

Compact, space-saving |

Larger, requires more panel space |

|

Locking Mechanism |

Push-pull latch, precise alignment |

Push-pull latch, more robust but bulkier |

|

Port Density |

High, ideal for dense installations |

Lower, suited for legacy or spacious layouts |

|

Optical Performance |

Low insertion loss, stable for high-speed networks |

Reliable for general use, varies by installation |

|

Cost |

Slightly higher, optimized for high-density builds |

More affordable, common in existing systems |

|

Typical Applications |

Data centers, telecom, high-capacity equipment |

Industrial, legacy networks, point-to-point links |

For fiber optic systems to deliver reliable, high-speed performance, selecting the right connector type is more than a mechanical decision — it directly impacts port density, space efficiency, and long-term scalability. Below is a comprehensive comparison of LC and SC SFPs, designed to help engineers, integrators, and network planners understand their practical differences in real-world environments.

The SFP module LC connector is specifically designed with space efficiency in mind. Featuring a compact housing and a 1.25mm ferrule, it enables higher port density within the same physical area. This smaller footprint is essential for modern data centers, high-capacity telecom equipment, and any scenario where maximizing rack space is a priority.

In comparison, the SC connector incorporates a larger 2.5mm ferrule and a more substantial body. While this contributes to its mechanical robustness, it also increases the space requirements on faceplates or patch panels. As a result, SC SFPs are often found in older infrastructure or installations where space is readily available.

Compact yet reliable, LC connectors use a push-pull latching system that ensures precise fiber alignment even in densely populated setups. The design simplifies cable management and helps maintain stable connections, which is crucial when working with high port counts or confined spaces.

SC connectors also rely on a push-pull latch mechanism, but their larger structure inherently takes up more room. The added size, however, enhances mechanical durability, making SC connectors better suited for environments where ruggedness and ease of handling are more important than maximum density.

Thanks to its compact profile, the LC connector supports significantly greater port density within the same enclosure or rack space. This makes it the preferred option for next-generation networks, core switching equipment, and dense fiber patching environments, where scaling capacity without expanding the physical footprint is critical.

By contrast, the SFP SC connector's larger dimensions inherently limit how many ports can fit on a panel. Nonetheless, it remains a practical solution for legacy systems or installations where port density is less critical, and mechanical robustness is preferred.

SFP module LC connectors are engineered for stable optical performance, offering low insertion loss and high repeatability when properly terminated and installed. They are widely deployed across both short-distance links and extended fiber runs, providing the signal integrity required for high-speed data transmission.

While SFP SC connectors also deliver reliable performance for general applications, their larger size and lower port density can make maintaining optimal alignment more challenging in space-constrained setups. Nonetheless, they remain effective in legacy networks or scenarios where ultra-high density is not a requirement.

The compact design and precision manufacturing of LC connectors can result in slightly higher costs, particularly for premium-grade components. However, the investment is often justified by the space savings and enhanced network scalability they provide, making them ideal for mission-critical data centers, telecom facilities, and evolving high-speed networks.

Simpler and more cost-effective, SFP module SC connectors continue to be widely used in established fiber infrastructures, point-to-point links, and industrial applications where space optimization is secondary. Their durability and ease of use make them a dependable choice for straightforward fiber optic connections.

The decision between SFP module LC and SC connectors should be based on a combination of technical requirements, space limitations, and the type of network environment you are working with. For space-constrained systems, especially in modern data centers, enterprise switching platforms, or high-capacity telecom applications, LC connectors typically offer a clear advantage. Their smaller footprint allows for significantly more ports to be integrated into patch panels or network equipment, supporting higher scalability without increasing physical infrastructure size.

In contrast, SFP SC connectors remain a practical choice for established networks, basic fiber links, or industrial environments where physical space is more readily available, and maximizing port density is not a primary concern. The larger structure of SC connectors contributes to their mechanical durability, which can be beneficial in installations requiring ruggedness or ease of manual handling.

It is also essential to evaluate your existing infrastructure. If your current setup primarily utilizes SC interfaces, introducing SFP module LC connectors may involve additional adapters, conversion hardware, or cabling updates. Conversely, for new projects where future network growth and space efficiency are top priorities, designing around LC connectors from the start provides greater flexibility for system expansion.

By carefully weighing factors such as available space, application complexity, long-term upgrade paths, and hardware compatibility, you can make an informed decision that aligns with both your immediate project needs and your network’s future evolution.

Learn more:

https://www.glgnet.biz/articledetail/sfp-cage-compatibility-escape-vendor-lock-In-save-costs

https://www.glgnet.biz/articledetail/sfp-port-technology-insights-understanding-the-basics

Conclusion

Both SFP LC and SFP SC connectors have their place in modern and legacy network infrastructures. While LC connectors are ideal for maximizing port density in space-constrained, high-performance environments, SC connectors offer a cost-effective and durable solution for existing systems or simpler fiber deployments.