Whether you're designing consumer electronics, industrial systems, or enterprise infrastructure, selecting the right RJ45 connector is more than a formality—it's a decision that affects performance, durability, and compliance.In this guide, we’ll walk through what an RJ45 jack connector is, the key selection factors you should consider, common mistakes to avoid, and engineering best practices for a smooth and successful integration.

Learn more:

https://www.glgnet.biz/choosing-right-rj45-jack

1.What Is an RJ45 Jack Connector?

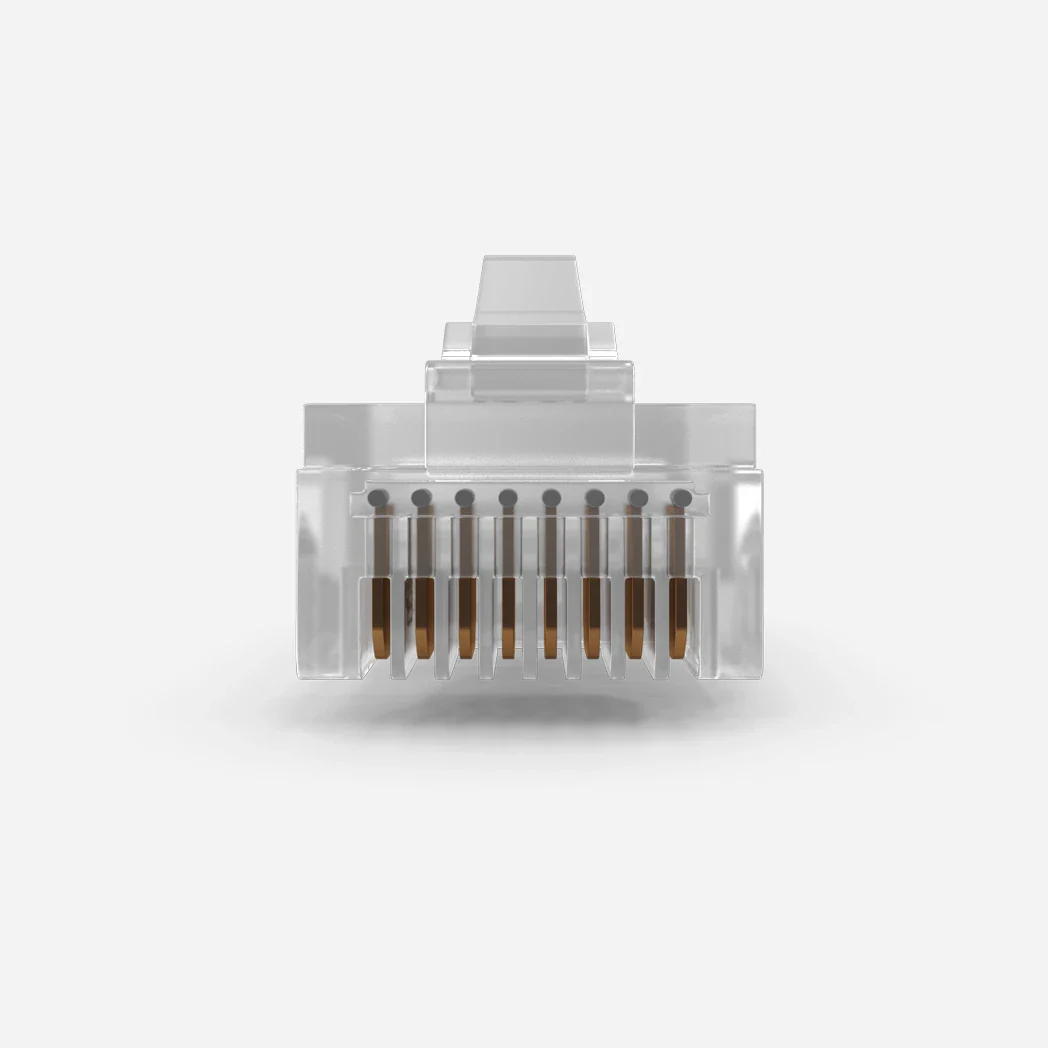

An RJ45 jack connector is a widely used interface in Ethernet and network communications. Also known as an 8P8C (8 positions, 8 contacts) modular connector, it supports high-speed data transmission and, in certain applications, Power over Ethernet (PoE).

These RJ45 connectors are found across a range of environments—from home routers and office networks to industrial machinery and IP surveillance systems. Their popularity stems from a compact footprint, secure locking mechanism, and broad compatibility with different Ethernet cable categories.

The term “RJ45 jack connector” can refer to different components. The plug is the male connector attached to the end of a cable, while the jack is the female socket typically mounted on a device or PCB. Understanding the distinction between these two elements is essential for proper component selection and reliable system integration.

2.Simplified RJ45 Connector Selection Guide

|

Factor |

Options |

|

Shielding |

Shielded (STP) / Unshielded (UTP) |

|

Magnetics |

With / Without |

|

LEDs |

With / Without |

|

Mounting |

THT / SMT Right-angle / Vertical |

|

Cable Type |

Cat5e / Cat6 / Cat6A / Cat7 |

|

Speed Support |

10/100 Mbps / 1G / 2.5G / 10G |

|

Durability |

Waterproof (e.g., IP67) Locking & cycles |

|

PoE Support |

IEEE 802.3af / at / bt |

3. Mistakes to Avoid When Choosing RJ45 Jack Connectors

Even a small mismatch in rj45 modular jack connector selection can lead to signal degradation, system instability, or premature product failure. Here are four common mistakes to watch out for—and how to avoid them:

3.1 Neglecting Signal Shielding Requirements

Choosing an unshielded rj45 modular jack connector for environments with high electromagnetic interference (EMI) can lead to data loss or network instability. This is especially problematic in industrial settings or near power lines, motors, or RF devices. Always evaluate whether a shielded (STP) connector is necessary to maintain signal integrity—especially when dealing with high-speed or long-distance Ethernet connections.

3.2 Using the Wrong RJ45 Jack Connector Orientation

RJ45 connectors come in various PCB mounting orientations, such as vertical, right-angle, and panel-mount styles. Selecting the wrong one can cause mechanical interference with other components or make the assembly process inefficient. Before finalizing the design, confirm the mating direction and layout constraints on your PCB, and request a 3D model or footprint from the supplier if needed.

3.3 Overlooking PoE Requirements

Not all connectors are designed to handle Power over Ethernet (PoE), which delivers both power and data through a single cable. If your application uses IP cameras, VoIP phones, or PoE-powered sensors, ensure the connector meets the relevant IEEE 802.3af/at/bt standard. Also, verify the voltage and current ratings to avoid overheating or long-term degradation.

3.4 Underestimating Environmental Demands

A connector that works well in a controlled indoor environment may fail quickly when exposed to moisture, dust, or temperature extremes. For outdoor or harsh-use applications, choose RJ45 jacks with IP67 sealing, corrosion-resistant materials, and a wide temperature range. Failing to do so can result in expensive maintenance or signal failure in the field.

4. Pro Tips for Engineers and Buyers

Selecting the ideal female rj45 connector requires more than matching part numbers on a datasheet. From mechanical integration to global compliance, multiple practical factors influence whether a connector will truly function as intended in your product. The following four expert tips can help engineers and buyers avoid common pitfalls and ensure a smooth transition from prototype to mass production.

4.1 Validate Mechanical Drawings and PCB Compatibility

To begin with, before committing to any specific female rj45 connector, it is essential to thoroughly review the mechanical drawing and recommended PCB footprint provided by the manufacturer. Critical aspects to examine include pin pitch, pad dimensions, solder tail lengths, and mounting hole locations. Even if two connectors share the same pin count, their physical configurations may differ slightly depending on the supplier or product series. These subtle variations can result in misalignment, poor solder joints, or interference during board assembly.

In addition, if you are updating or replacing a connector in an existing (legacy) design, be especially cautious. What appears to be a drop-in replacement may introduce unexpected design challenges due to small differences in latch orientation, board retention mechanisms, or mounting tab locations. Catching these mismatches early can save you from costly rework or assembly failures down the line.

4.2 Use 3D Models to Ensure Physical Design Integration

Equally important is verifying how the rj45 modular jack connector connector fits into your overall mechanical design. Many integration problems only become apparent after PCB fabrication or enclosure molding—by which point changes are time-consuming and expensive. To avoid this, always request a 3D CAD model (typically in STEP or IGES format) of the RJ45 connector and import it into your mechanical design software.

This allows you to confirm key factors such as vertical clearance, overall height profile, side-to-side spacing, and access for tools or users. If the design involves a panel-mount configuration, ensure that the connector aligns properly with the panel cutout. Also, verify that nearby components, heat sinks, or mechanical structures do not obstruct the connector. Taking these steps early improves collaboration between mechanical and electrical teams and helps prevent last-minute design revisions.

4.3 Test Mating Performance Under Real Conditions

Beyond drawings and models, real-world fit testing is crucial to assess how the RJ45 jacks will actually perform in its intended environment. While datasheets specify mechanical durability and mating cycles, they can’t fully reflect how the connector behaves with actual cables and plugs. Therefore, during prototyping, it’s important to test the rj45 connector with the same plug or patch cord that will be used in production.

Pay close attention to the insertion and extraction force—does the plug go in smoothly, or is it excessively tight or loose? Evaluate the latch retention strength, especially in scenarios involving vibration or repeated plugging. Also, consider the tactile feedback, as a clear and reliable “click” can significantly impact user experience. These mechanical nuances, though small, can affect product quality and reliability, particularly in industrial or portable applications.

4.4 Evaluate Supply Stability and Regulatory Compliance

Finally, beyond technical and mechanical compatibility, it’s vital to ensure that the selected rj45 jack connector can be sourced consistently and meets required compliance standards. Before locking in a part for your BOM, check the manufacturer’s lead times, availability in your region, and whether they offer long-term supply guarantees. This is particularly important for high-volume or long-lifecycle projects, where component changes midstream can lead to production interruptions.

At the same time, confirm that the part complies with relevant regulatory standards, such as UL, CE, RoHS, and REACH. These certifications are not only critical for market access, especially in international or regulated industries, but also signal reliability and safety. If in doubt, request documentation from the supplier, including compliance declarations and long-term supply plans. Taking these steps upfront helps avoid potential sourcing risks, audit failures, or product launch delays.

Learn more:

https://www.glgnet.biz/top-10-rj45-jack-manufacturers

https://www.glgnet.biz/how-to-test-rj45-jack-connections-a-complete-guide

https://www.glgnet.biz/how-to-choose-between-sfp-and-rj45-connectors-for-your-network

Conclusion:

Choosing the correct RJ45 jack connector may seem straightforward, but the right decision can make a significant difference in product performance and long-term reliability. From shielding and mounting style to PoE support and mechanical fit, every detail matters—especially when working with female RJ45 connectors in demanding environments.