With thicker conductors, bulkier insulation, and often shielded construction, Cat6A cables demand more from your connectors—both in terms of fit and function. In this guide, we’ll break down the key factors to consider when selecting the best RJ45 connector for Cat6A cable, from shielding types to compatibility tips and termination methods.

Learn more:

https://www.glgnet.biz/how-to-connect-cat6-cable-to-rj45-racket-rj45-connector

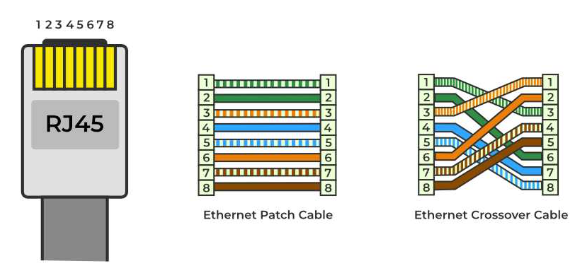

Cat6A cables are designed to support stable 10 Gigabit Ethernet over distances up to 100 meters, which makes them ideal for high-speed, high-traffic environments. Compared to older cables like Cat5e or Cat6, Cat6A has a thicker construction and often includes shielding to reduce electromagnetic interference.

However, this added size not only improves performance, but also means Cat6A cables aren’t compatible with standard RJ45 connectors. The wires are thicker, and the insulation is tighter—so you need connectors that are specifically made to accommodate them.

If not, using the wrong connector can lead to poor terminations, signal loss, or lower transmission speeds. Therefore, to get the full benefit of Cat6A, it’s essential to use RJ45 connectors that match both the cable’s physical dimensions and its shielding type.

In short, the connector matters just as much as the cable itself—especially when you're aiming for reliable, high-speed network performance.

|

Feature/Aspect |

Shielded RJ45 (STP/FTP) |

Unshielded RJ45 (UTP) |

|

Cable Compatibility |

For shielded Cat6A cables |

For unshielded Cat6A cables |

|

EMI Protection |

Excellent – protects against electrical noise and interference |

Minimal – relies on proper routing to avoid interference |

|

Use Environment |

Industrial areas, data centers, hospitals, high-EMI zones |

Homes, small offices, low-interference environments |

|

Installation Difficulty |

Slightly more complex – requires grounding and shielding care |

Easier and faster – more flexible cable handling |

|

Cost |

Generally more expensive |

More cost-effective |

Learn more:

https://www.glgnet.biz/shielded-vs-unshielded-rj45-jack-which-one-fits-your-network

When installing Cat6A cables, choosing between a shielded (STP/FTP) or unshielded (UTP) RJ45 connector is a key decision that can directly impact your network’s performance and reliability.

Shielded RJ45 connectors are designed to work with shielded Cat6A cables, offering strong protection against electromagnetic interference (EMI). This makes them ideal for environments with high electrical noise, such as factories, data centers, hospitals, or spaces filled with heavy equipment. The added shielding helps preserve signal quality over longer distances and ensures consistent network stability.

In contrast, unshielded RJ45 connectors pair with unshielded Cat6A cables and are often preferred for homes, small offices, and other low-interference settings. They’re easier to handle, more flexible during installation, and generally more budget-friendly—without sacrificing performance in clean electrical environments.

To choose the right connector, consider both your cabling type and installation environment. Using mismatched components—like pairing a shielded cable with an unshielded connector—can cancel out the shielding effect and reduce performance. For best results, make sure your cable, connector, and grounding setup are fully compatible.

In summary, choose shielded connectors if you're dealing with noisy or industrial environments, and unshielded connectors for simpler, interference-free installations. Matching the right connector to the right job ensures your Cat6A system performs the way it’s designed to.

When terminating Cat6A cables, you’ll typically choose between toolless and crimp-style (tool-type) RJ45 connectors. The best option depends on your installation scenario and how much speed or durability you need.

Toolless connectors are designed for fast, straightforward installation—no crimping tool required. You simply insert the wires into a guide cap and press them into place. This makes them ideal for DIY setups, office networks, or on-site jobs where carrying extra tools isn’t practical. They’re especially convenient when time and simplicity are priorities.

In contrast, crimp-style connectors require a crimping tool but offer a more compact and secure connection. They’re the standard in professional installations, such as patch panels or structured cabling projects, where long-term reliability is key. Though they take slightly more effort to install, they’re favored for their durability and consistent performance.

In summary, toolless connectors are great for quick jobs and small-scale use, while crimp-style connectors are better suited for demanding or permanent installations.

Ensuring proper fit between your Cat6A cable and RJ45 connector is essential for a reliable, high-performance network. Here are the key factors to check before installation:

Cat6A cables are typically built with 23 AWG solid copper conductors—slightly thicker and stiffer than the 24 or 26 AWG wires found in Cat5e or Cat6. This extra thickness provides better signal transmission over longer distances but also means not every RJ45 connector is suitable. If the connector’s contact channels are too narrow, the wires may not seat correctly, leading to unstable connections or weak electrical contact. Over time, this can cause intermittent performance issues or even complete failure. To avoid this, always confirm that your connector explicitly supports 23 AWG solid conductors before terminating.

Beyond the conductor size, Cat6A cables also have a noticeably larger outer diameter. This is due to reinforced insulation, pair separators, and in many cases, additional shielding. While this bulk helps maintain signal integrity and reduce crosstalk, it also requires a connector with enough internal space to accommodate the jacket. If you use a connector designed for thinner cables, you may need to strip back too much of the jacket, which can compromise mechanical strength and expose shielding to potential interference. A properly sized connector allows the cable to fit snugly without deformation, preserving both the physical integrity and shielding performance.

RJ45 connectors are not always one-size-fits-all, especially when it comes to structured cabling systems like wall plates or patch panels. Some connectors may be slightly too large or shaped differently, preventing them from locking cleanly into keystone jacks. This is particularly important in high-density environments where space is tight and precision matters. To avoid frustration during installation—and to ensure professional-looking results—check that the connectors are labeled as “keystone-compatible” or tested with your specific jack and panel brand.

A well-built cable is only as strong as its weakest component. Even if you’ve invested in high-quality Cat6A cable, using a subpar connector can bottleneck performance. To ensure your network runs at full 10 Gigabit speed, the RJ45 connector must also meet ANSI/TIA-568.2-D standards and be rated for 10G Ethernet. Certified connectors are tested for performance factors like signal return loss, crosstalk, and contact resistance. While non-certified products might seem cost-effective, they can introduce signal degradation that’s hard to trace but easy to avoid with proper components.

It’s a common mistake to assume that all RJ45 connectors are interchangeable as long as the plug fits. However, Cat6 and Cat6A connectors often differ in subtle but critical ways. For instance, Cat6 connectors may have narrower wire guides or reduced shielding support, which won’t properly accommodate the larger, stiffer build of Cat6A cables. This mismatch can lead to misaligned contacts, inadequate shielding continuity, and ultimately, reduced signal quality. Always use connectors that are specifically designed for Cat6A—not just "compatible"—to ensure your termination is both physically secure and electrically optimal.

Learn more:

https://www.glgnet.biz/is-your-rj45-connector-the-problem-check-it-at-home

https://www.glgnet.biz/how-to-choose-between-sfp-and-rj45-connectors-for-your-network

https://www.glgnet.biz/cat5e-vs-cat6-rj45-jacks-which-one-should-you-choose

Conclusion

Not all RJ45 connectors are created equal—especially when you're working with Cat6A cables. From shielding type and conductor size to fit and certification, every detail matters if you want to maintain reliable 10G performance. Whether you're wiring a data center or upgrading a home network, choosing the right connector for your Cat6A cable ensures signal integrity, long-term stability, and a hassle-free installation process.